Edge Strips

MasQ Edge Strips

Our range of components includes:

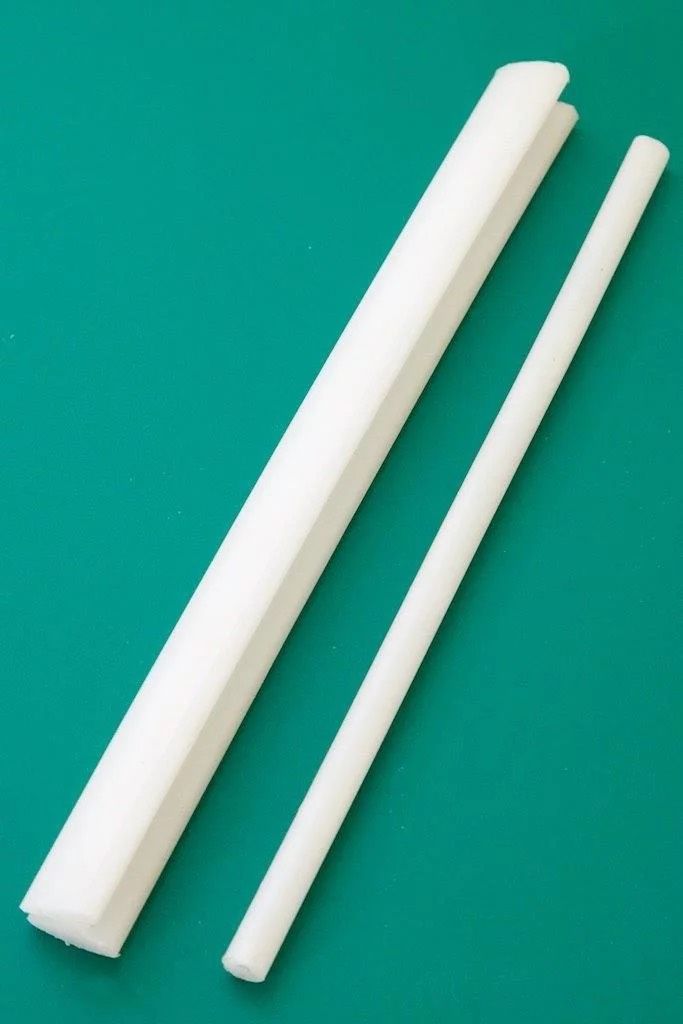

MasQ – H Type Edge Strip

The MasQ H-Type edge strip makes use of pinch mechanics by using an oversized rod to create a clamping effect.

This design allows for a strong fit on cathode plates.

The design allows for a two sided or three sided edge strip assembly.

This Edge strip is easy to install and remove. It is extremely tough and is resistant to high temperatures as well as high resistance to corrosion, while remaining flexible and durable.

Due to its simple nature it is cost effective when compared to traditional edge strip systems.

MasQ Edge strips can be manufactured to any size.

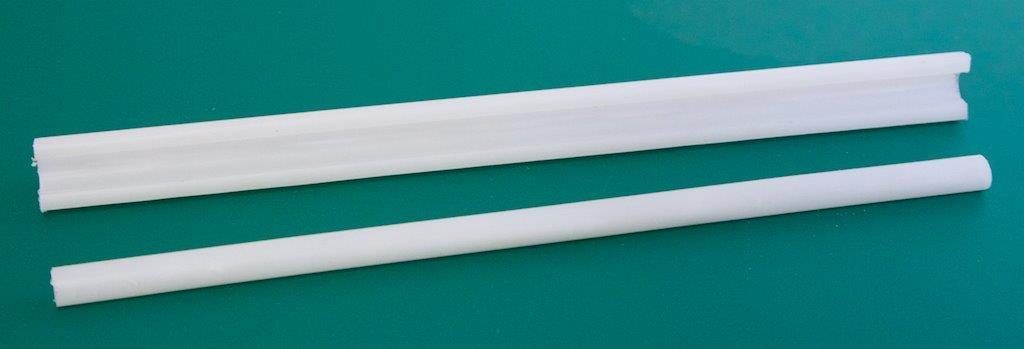

MasQ – Cross Slotted Edge Strips

Cathode edge strips prevent build-up of metal round the edges facilitating the stripping of copper.

Made from high quality, high impact strength PVC these edge strips combine flexibility with strength and durability.

Available in two sections they are supplied cut to length to suit each individual plant.

MasQ Corner Boots

When a bottom strip is used corner boots are fitted to both seal and protect the mitred corners.

Available to suit both sections of edge strip they are injection moulded from a high grade PVC and retained in place using a commercial grade PVC glue during assembly.

MasQ Retainer Strips

Retainer strips are used to ensure the edge strips remain on the cathode.

The pins locate into holes drilled along the sides of the cathode (and the bottom where bottom strips are used).

The retainer strips then align with the slots in the edge strip during assembly. The retainers are precision injection moulded and are available in 5 and 6 pin configurations.

They are supplied complete with re-usable drive type fixings.

MasQ Top Pins

Top pins are used to fix the edge strip to the cathode to prevent the strip from sliding off.

One pin is used per side strip and locates through holes drilled into the top of the edge strip and the cathode.

MasQ – Moulded, U-Shaped Edge Strip

Our one-piece, three-sided track type assembly features integrally moulded corner boots and a bottom edge strip to:

- Reduce costs on maintenance

- Increase harvest cycles

- Extend Cathode Lifespan

Durable, injection moulded corner pieces:

- Cleaner cathode edges

- Improves cathode quality

- Makes stripping easier

- Protects against metal nodulation at the cathode bottom corner

- Eliminate potential for short circuits and reduced plant efficiency

- Protects the bottom Cathode corner and avoids damage to the Cathodes

- Protect against anode insulator damage caused by knife edge “v” groove at cathode bottom