Screen Panel Systems

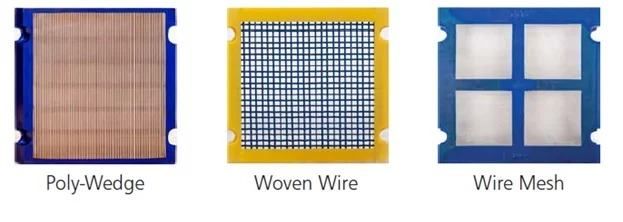

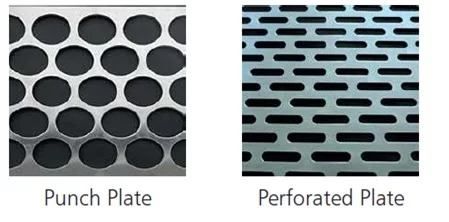

The MasQ range of polyurethane screen panel systems is extremely durable and cost-effective. Featuring new corrosion engineering technology, our injection-moulded panels offer noise absorption and wear-cycles that either match or exceed those of conventional woven wire or perforated steel plate panels.

MasQ polyurethane screen panels offer cost-effective, long-lasting separating and sizing of all types of minerals and earths. Our proven panels are ideal for use in all mine and quarry stone-crushing and sand-handling plants.

Benefits of Screen Panel Systems

-

Cost-effective

-

Longer lifespan

-

Improved wear-resistance

-

More open area

-

Added reinforcement

Features

-

Draining Deflection (DDF) – Channelling material and fluid from dead areas to apertures for increased screening efficiency.

-

Flow Restriction (RF) – Restricting flow of product to increase time spent on screening surface to maximise screening efficiency.

-

Carrier Bars (CBs) – Increasing life expectancy and efficiency by lifting large particles above apertures. The screenable particles are forced to traverse more apertures to further improve efficiency.

-

L-Shape (25-200mm) Increasing de-watering efficiency or product rinsing.

-

Dividers – Generating two streams of screening on one deck.

-

Four pin and sleeve fastening (round) – Standard four pin and sleeve approach and oversized pins are available for slightly worn fixing holes on support frames.

-

Injection moulded – High-speed, high-quality production ensuring that every panel has accurate opening sizes and shapes and is thoroughly cured throughout.

Types of Screen Panels Available:

-

Standard – 305 x 305 x 31mm and 305 x 305 x 35mm with square, slotted and VR apertures of between 0.3mm to 70mm (please enquire for a list of all available panel options)

-

VR Self Cleaning – Non-blind and Pegging

-

VRA Panel (Patented) – Aperture is moulded at an angle to increase throughput

-

Solid Panel – For high impact or abrasion applications, e.g. feed end and discharge

-

Wire Insert Panel

-

Specials – Including round teardrop and angled round

Proven solutions, fast lead times, excellent customer service

Whether you are looking for a proven solution to reduce your screening costs-per-ton, want to take advantage of our conveniently fast production and lead-times or to experience our excellent customer service, please contact us to find out more about our polyurethane screen panels.